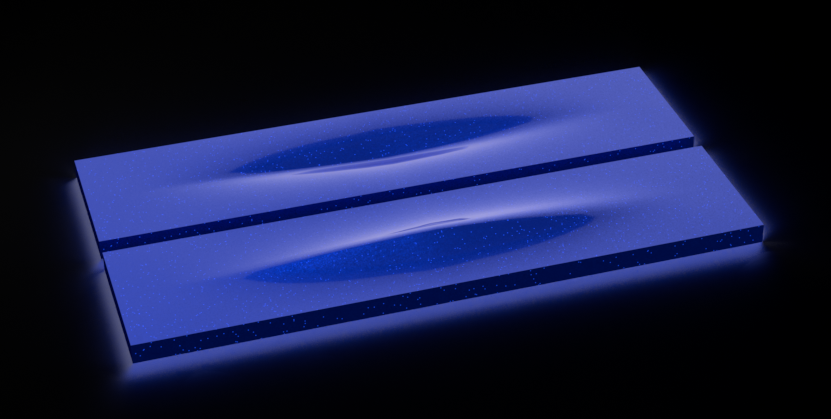

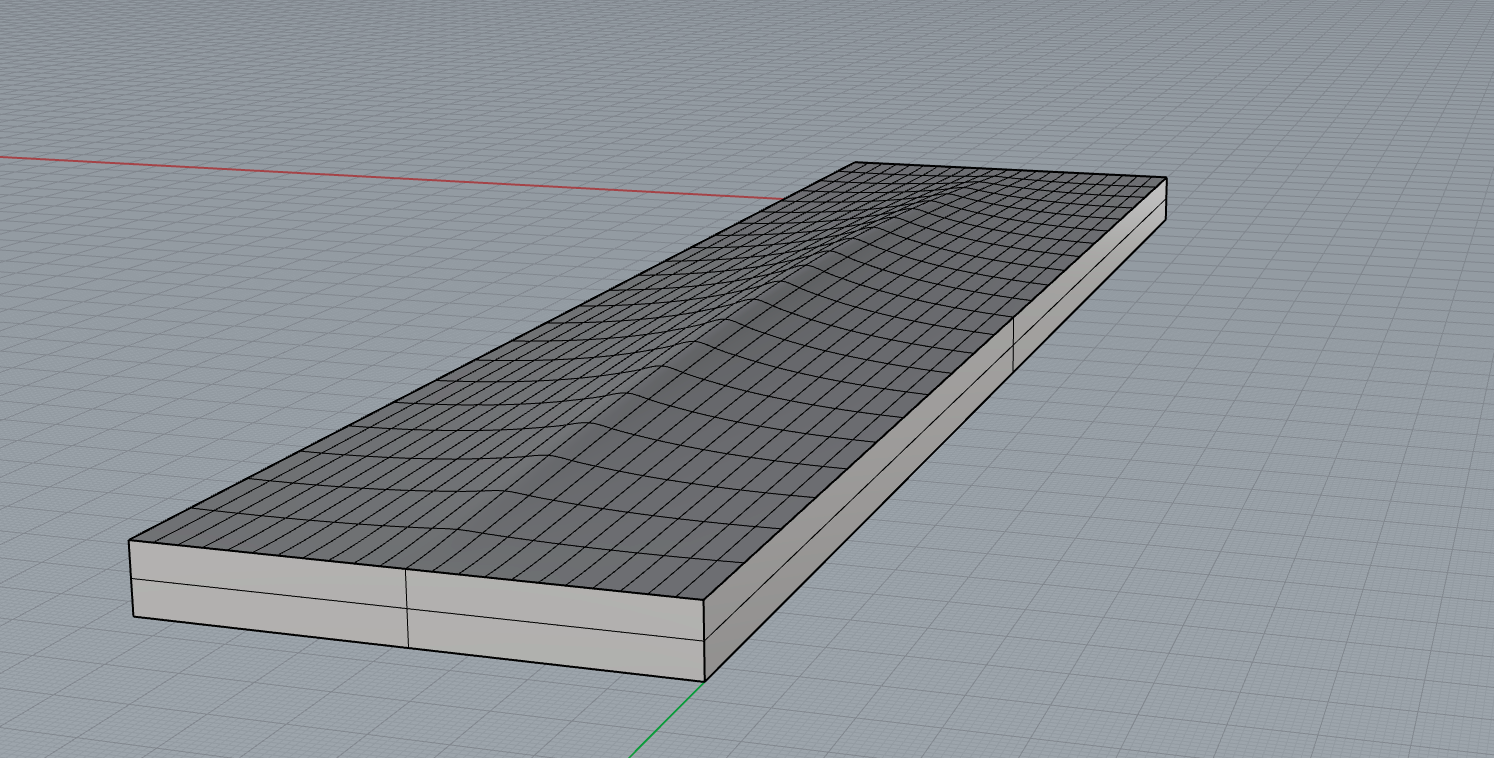

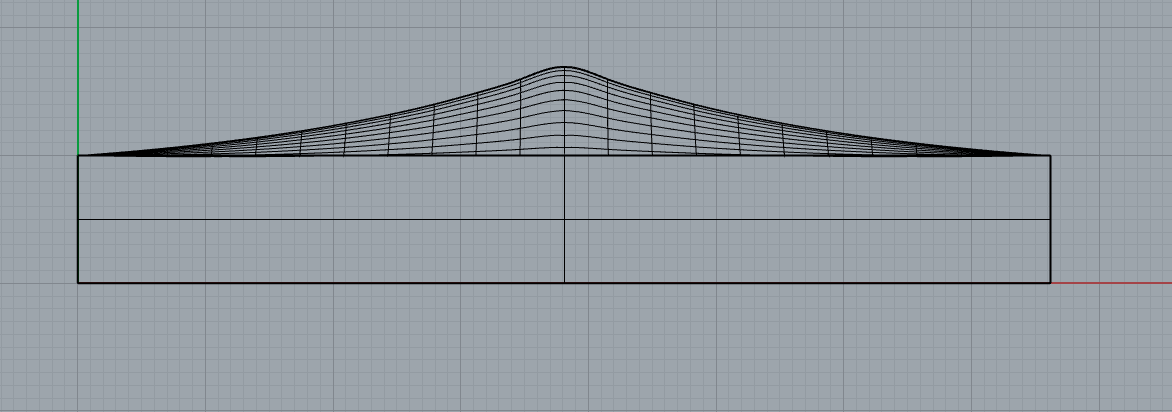

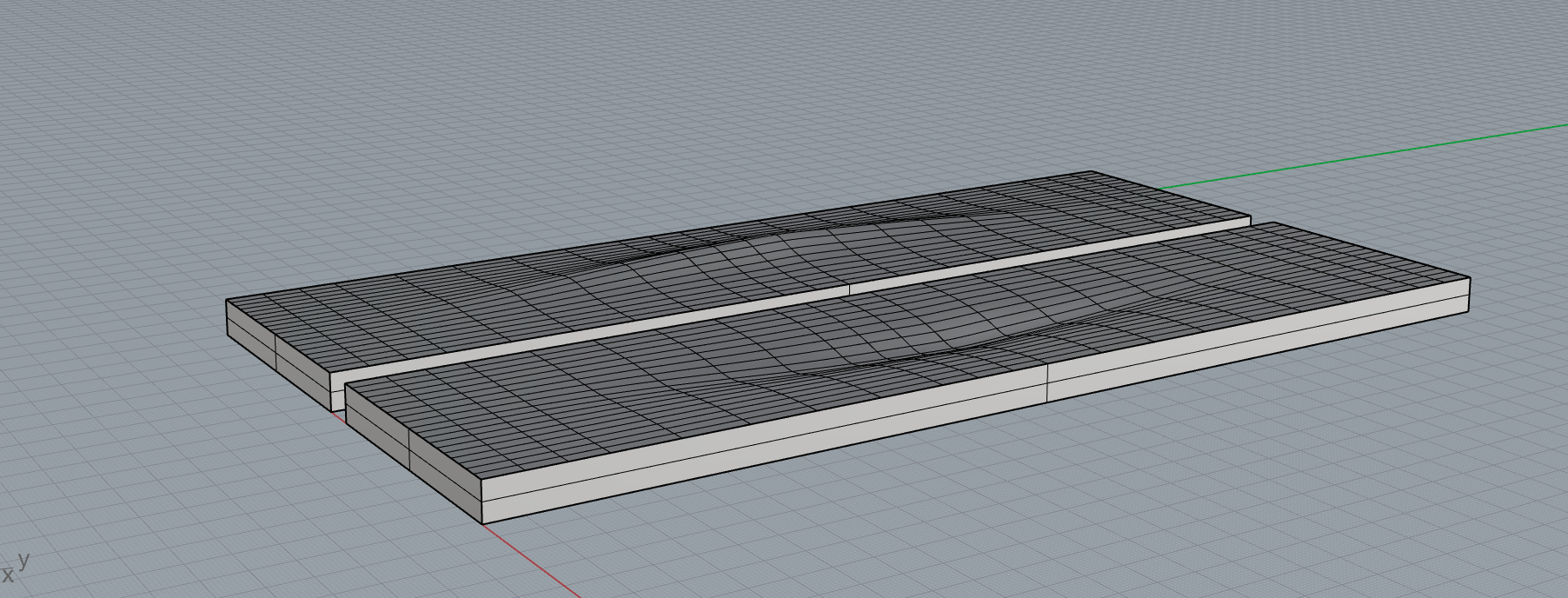

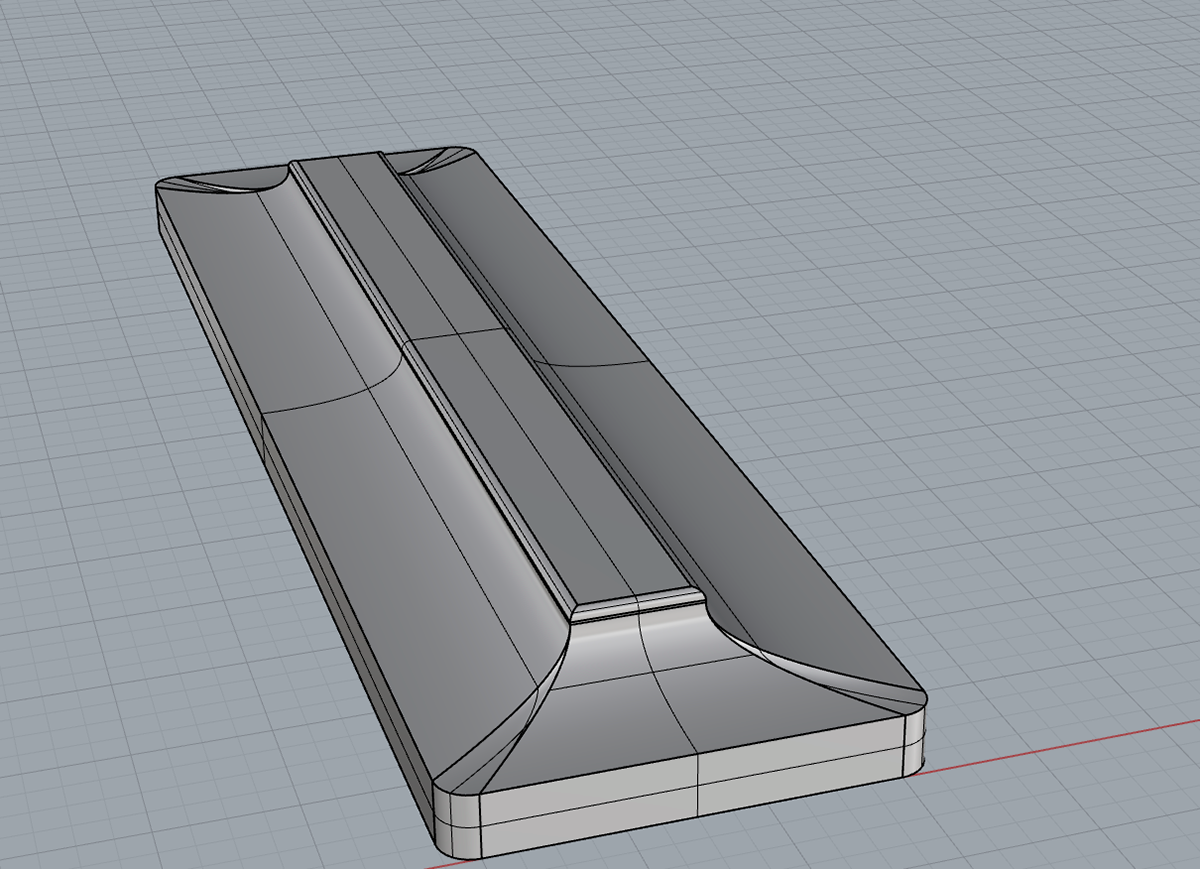

While working with Eddie Bedrosian, we created a pair of coordinating tiles, one concave and convex, that will be used as a mold for the factories for an upcoming collection. These 3D prints were sent to factories as a way to make molds for the tiles on the production line. With Rhinoceros 6, I created digital models of the tile designs, allowing for easy customization and modification. Once the design was complete, it was exported to a 3D printer to create a physical version of the tile. This 3D printed model was then sent to our factory to be used as a reference for the tile creation process. Using the 3D printed model as a guide, Bedrosians creates tiles that are exact replicas of the original design. This process allowed for greater precision and accuracy in the tile creation process. It also allows for easy modification and experimentation with different tile designs without the need for costly and time-consuming physical prototypes.

Below is my process where we created 7 versions of the shape until the idea was exactly what Bedrosians was thinking of. This project is in the pipeline and will one day be on store shelves.

3D Print Iterations